Manganese ore processing

1. Washing and screening

Washing is the use of hydraulic washing or additional mechanical scrubbing to separate the ore from the mud. Commonly used equipment includes washing sieves, cylinder washing machines and tank washing machines.

The washing operation is often accompanied by screening, such as direct flushing on the vibrating screen or sifting the ore (net ore) obtained by the washing machine to the vibrating screen. Screening can be used as an independent operation to separate products of different sizes and grades for different purposes

2.Gravity method

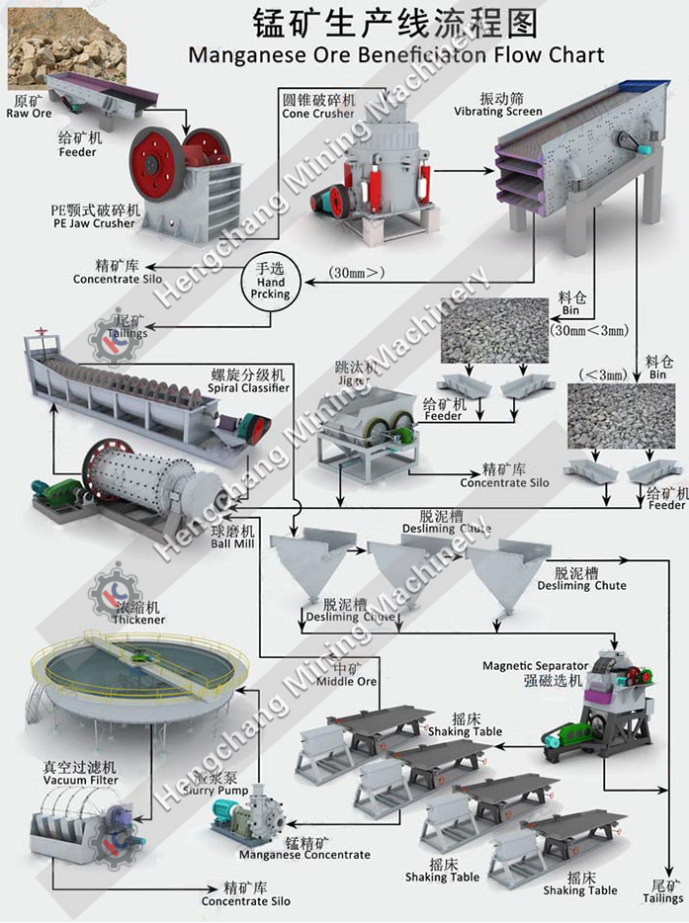

Gravity method is only used to select manganese ore with simple structure and coarse grain size, especially suitable for manganese oxide ore with high density. Common methods include heavy medium dressing, jigging and shaker dressing.

At present, the process of processing manganese oxide ore in China is generally to crush the ore to 6~0mm or 10~0mm, and then group, coarse-grade jigging, and fine-level shaker table selection. Most of the equipment are saw-tooth wave jigging machine and 6-S shaking table.

3.4. Gravity method + magnetic separation

It mainly treats leaching manganese oxide ore, and uses a jig to treat 30~3mm of cleaned ore. It can obtain high-quality manganese concentrate containing more than 40% of manganese, and then can be used as battery manganese powder after hand-selection. After jigging tailings and less than 3mm washing ore grinding to less than 1m, the selection of manganese ore concentrate should be increased by 24%~25%, reaching 36%~40%.

4.5. Strong magnetic + flotation method

It is mainly used for low manganese, low phosphorus and high iron manganese ore mainly composed of manganese carbonate ore.