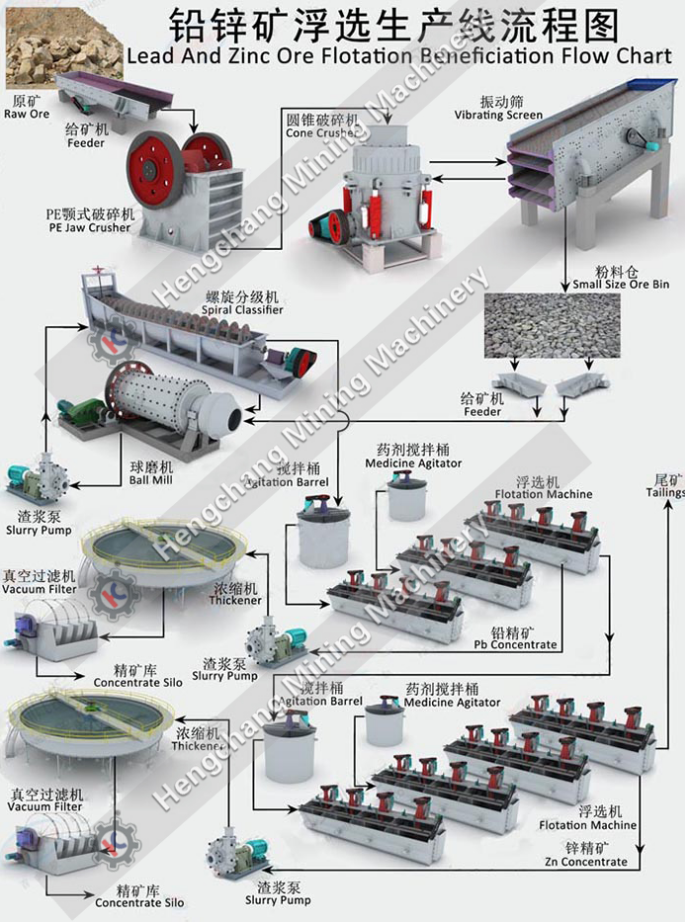

Lead and zinc ore processing

The lead-zinc ore mine enters the mixing tank after being crushed and grind powder, and then enters the flotation machine. The lead concentrate is first mixed and then the zinc concentrate is floated. If it contains sulfur, the sulfur concentrate will float out.

Lead-zinc ore flotation equipment and useful:

Jaw Crusher, Cone Crusher: The ore is crushed to make the useful minerals and gangue minerals dissociate from the monomer.

Self-centering vibrating screen: The mixture material is divided into different grades according to the particle size, and the qualified granularity products are sorted to avoid over-grinding of the ore and improve the productivity of the crusher.

Ball mill: The ore is crushed to make the ore reach a finer particle size.

Hydrocyclone: Distribute qualified products in time to avoid over-grinding, and at the same time, separate unqualified coarse sand and return to grinding. : There is also the effect of concentration.

Flotation machine: The slurry is aerated and agitated, so that the ore particles whose surface has been subjected to the collector are attached to the bubbles, scraped off with a scraper to obtain a concentrate.

Thickener: The process of precipitating and concentrating the slurry to separate the thinner slurry from the clarified liquid and the slurry.

Filter: Remove most of the capillary water from the material.

In addition, there are some auxiliary equipment, such as electric vibration feeder, belt conveyor, mixing tank, mine bin, sand pump, pump pool, motor and so on.