Gravity Separator

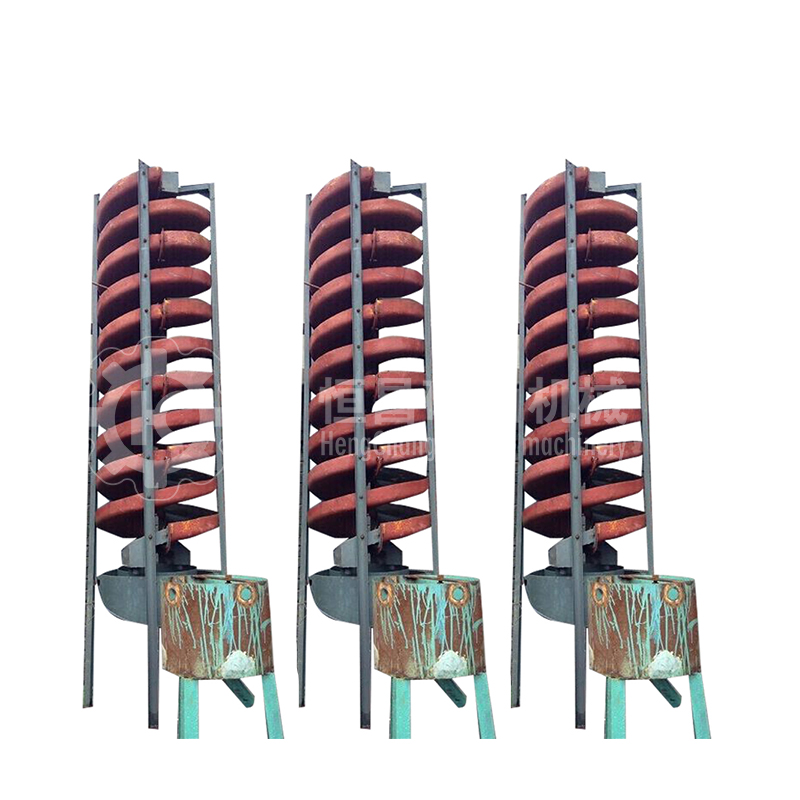

Product details

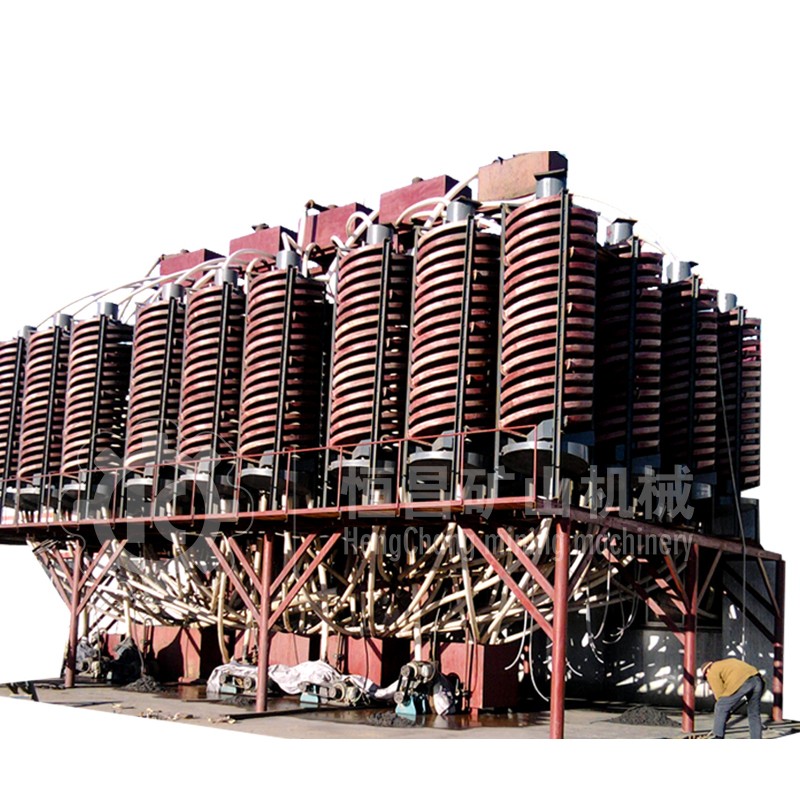

Introduction: Spiral chute is high efficient gravity equipment for mineral processing. It doesn’t need the power but utilize the different particles by the effect of gravity, water pressure and friction to achieve the separation of the useful minerals and gangue. It is made of the fiberglass with wear-resistant polyurethane and corundum cover.

Processing Materials: Gold, tin, columbium, tantalum, titanium, barium, tungsten, barite, chrome, manganese, zircon, lead, zinc, copper, aluminum, coal and some other materials.

Application Range: Spiral chute is suitable for processing iron, tin, tungsten, tantalum, chrome, niobium, gold, coal, monazite, rutile, zircon and other metal, nonmetal minerals with enough specific gravity dispersion of granularity ranged from 0.02 to 0.3mm lode and placer, but high mud content is bad for separation.

Advantages and Characteristics:

1. Reasonable structure and small occupation area.

2. High recovery, high efficiency, and precise separation.

3. Light in weight, rust and corrosion resistant.

4. Simple installation and Minimal maintenance requirements.

5. Low operating cost and long operating life.

6. Reliable running with minimal operator attention.

7. Strong adaptability to fluctuation of feeding amount, density, size and grade.

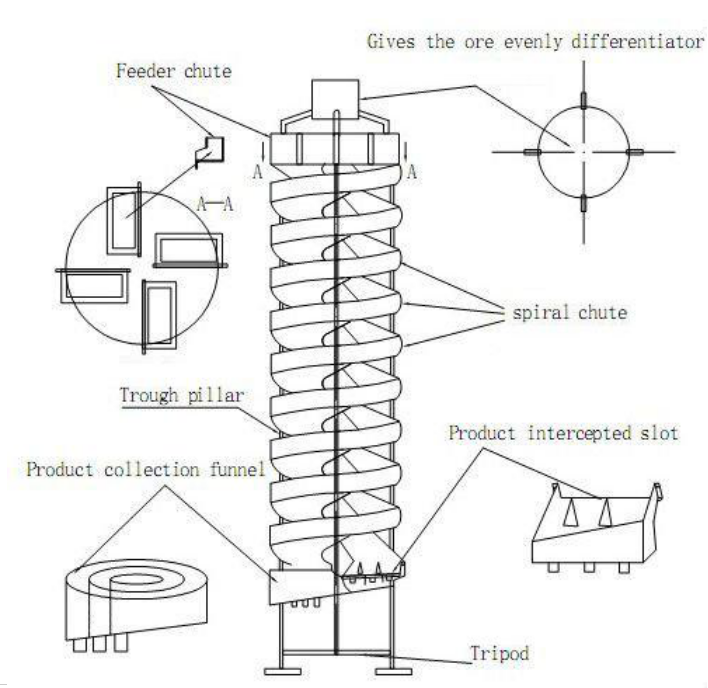

Working Principle:

Spiral chute is working under the force of water flow, gravity, inertial centrifuge and friction. Ore pulps are uniformly fed into machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into concentrate, middling and tailing.

Technical Parameter

Model | BLL-1500 | BLL-1200 | BLL-900 | BLL-600 | BLL-400 |

Outside Diameter (mm) | 1500 | 1200 | 900 | 600 | 400 |

Screw Pitch (mm) | 900, 675 | 900, 720, 540 | 675, 540, 405 | 450, 360, 270 | 240, 180 |

Pitch Diameter Ratio | 0.48, 0.36 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.6, 0.45 |

Lateral slope (degree) | 9° | 9° | 9° | 9° | 9° |

Max. Screw Numbers Per Set | 4 | 4 | 4 | 2 | 2 |

Feed Size (mm) | 0.8 ~0.037 | 0.3~0.03 | 0.3 ~0.03 | 0.2~0.02 | 0.2 ~0.02 |

Feed Density (%) | 30 ~55 | 25 ~55 | 25 ~55 | 25 ~55 | 25 ~55 |

Capacity (t/h) | 6~8 | 4~6 | 2~3 | 0.8~1.2 | 0.15~0.2 |

Length (mm) | 1600 | 1360 | 1060 | 700 | 460 |

Width (mm) | 1600 | 1360 | 1060 | 700 | 460 |

Height (mm) | 5300 | 5230 | 4000 | 2600 | 1500 |

Weight (kg) | 850/800 | 700/650/600 | 450/400/350 | 150/120/100 | 50 |